The Federal Aviation Administration (FAA) additionally stated that it discovered “non-compliance issues in Boeing’s manufacturing process control, parts handling and storage, and product control.” The FAA did not specify what corrective actions Boeing and Spirit must take, but it did send a summary of its findings to the firms in its finished audit.

Spirit AeroSystems, which manufactures the MAX fuselage, stated that it is “in communication with Boeing and the FAA regarding appropriate corrective actions.”

According to Boeing, “by virtue of our quality stand-downs, the FAA audit findings and the recent expert review panel report, we have a clear picture of what needs to be done.”

Boeing revealed on Friday that it is in talks to acquire Spirit AeroSystems, a former company that was spun off in 2005.

The FAA’s audit was prompted by a mid-air accident on January 5 involving a new Alaska Airlines (ALK.N), opens new tab 737 MAX 9 that lost a door plug at 16,000 feet (4,877 meters). The FAA already prohibited Boeing from increasing 737 manufacturing, and in January stated that “the quality assurance issues we have seen are unacceptable.”

Following an all-day meeting with CEO Dave Calhoun on February 27, FAA Administrator Mike Whitaker announced last week that Boeing must develop a detailed plan to fix “systemic quality-control issues” within 90 days.

“Boeing must commit to real and profound improvements. We are going to hold them accountable every step of the way, with mutually understood milestones and expectations.”

Mike Whitaker, FAA Administrator

Calhoun said in a statement last week that Boeing’s leadership team was “totally committed” to addressing FAA concerns and developing the plan.

Whitaker told in January the goal of the audit was “to look at the system, look at how the inspections are done, where they’re done, how the interaction is with the suppliers, how the handoff happens, just the whole process to really understand how it works and where the faults might be.”

Boeing has hurried to explain and tighten safety protocols following the mid-air mishap that caused the FAA to halt the MAX 9 for several weeks in January.

Whitaker stated that Boeing’s strategy must include the results of the FAA’s production-line audit as well as findings from an expert review panel study released last week.

One critical issue in the investigation into the incident is determining which manufacturing documentation were utilized to approve the opening and closing of the door plug while working on the plane.

Ed Clark, the head of Boeing’s 737 MAX program, was unceremoniously fired last month as part of a management shakeup.

Previously, a bipartisan group of lawmakers questioned the FAA if it discovered “any evidence of persistent quality control lapses in any of Boeing’s production lines.”

The FAA has been critical of a number of Boeing quality issues over the years. In 2021, Boeing paid the FAA a $6.6 million fine as part of a settlement for years of quality and safety monitoring breaches.

In December, the FAA advised airlines to assess MAX planes for loose bolts in the rudder control system after one identified a bolt with a missing nut during standard maintenance.

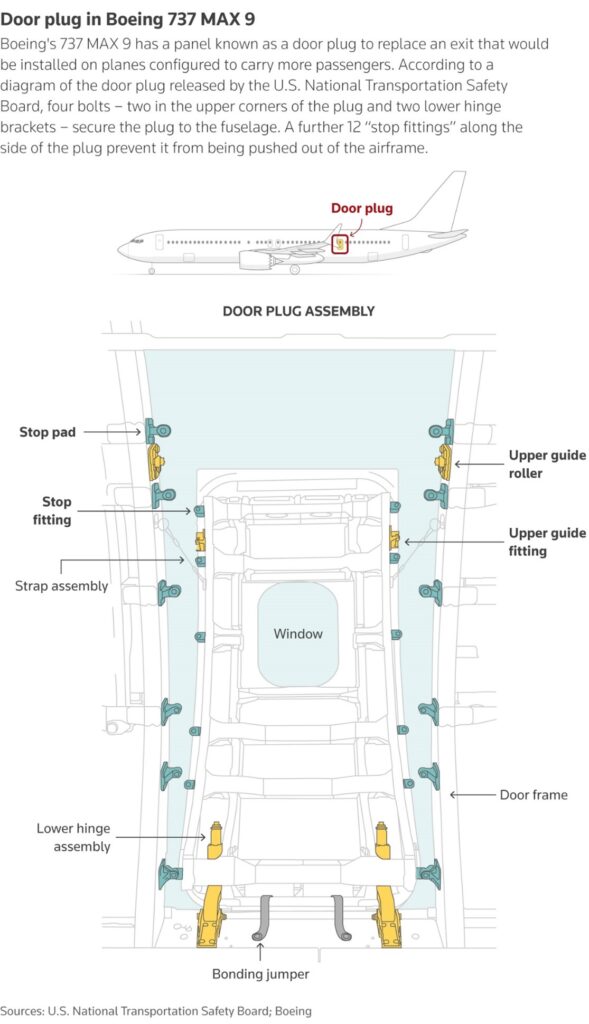

The door panel that fell off the MAX 9 seemed to be missing four essential fasteners, according to a preliminary investigation last month from the US National Safety.